We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Industries

Automation

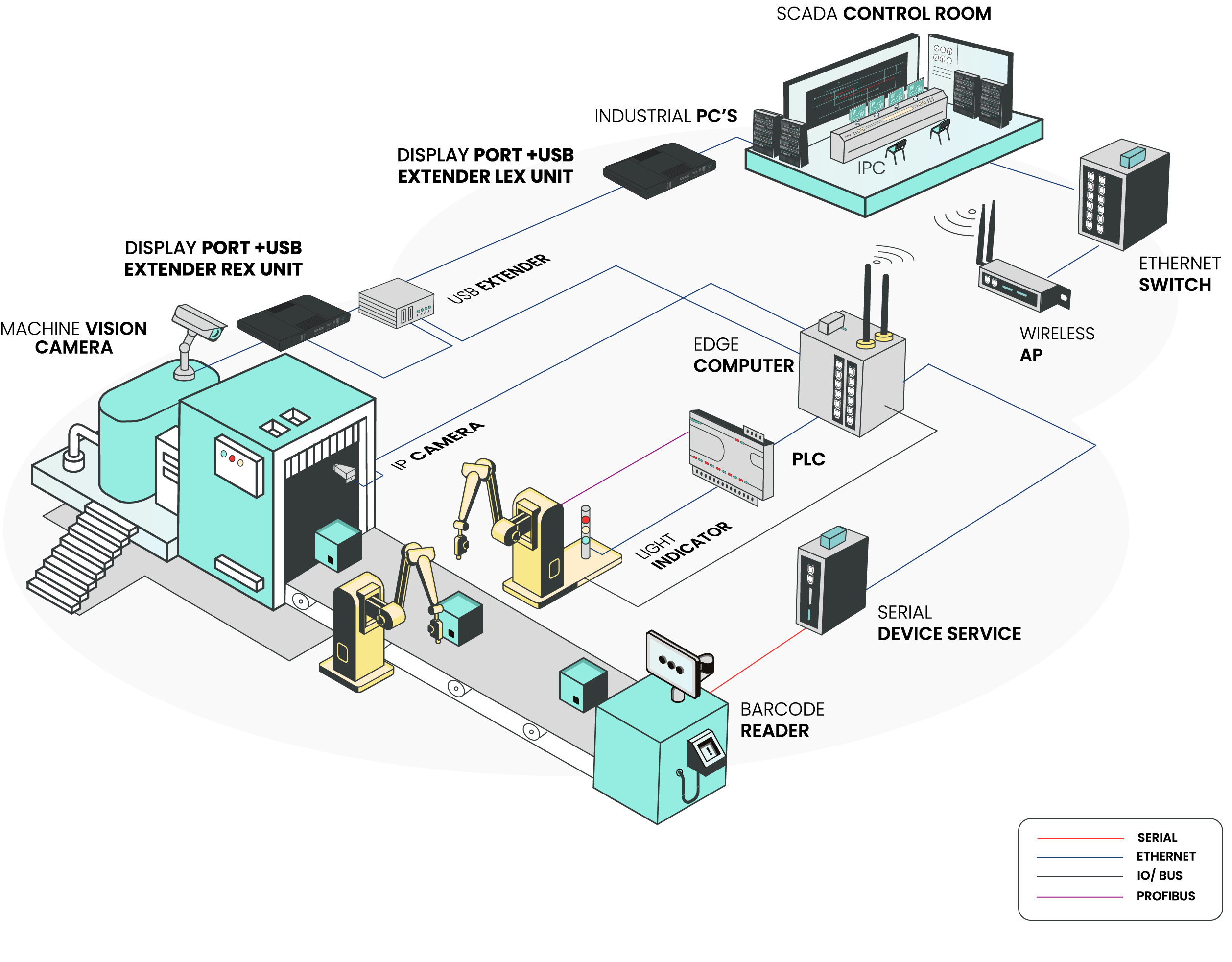

Industry 4.0 is here, and it offers Facility Managers access to Real-time “shop floor” data, supporting decision making, maintenance, and production planning. The ability to visualize data of your production equipment allows you to pre-emptively maintain and upgrade equipment, increasing productivity and reducing downtime.

Industry 4.0 does not just mean access to more data than ever; it also allows new levels of automation that will remove time-consuming and labor-intensive manual processes from your facilities.

Securely integrating different systems and legacy devices to allow you to remotely manage your facilities can be a complex process. Industrial IT industry specialists are here to understand your challenges and offer you bespoke IIoT solutions to help you improve efficiency and productivity

Smart Factories

Creating a smart factory, that connects key systems both on your production line and for facilities management creates benefits in efficiency, cost, reliability, and downtime.

Smart networks will allow multiprotocol connectivity in both decentralized systems, differing brand equipment, and seamless integration into SCADA and MES systems.

These networks provide predictive maintenance, high longevity, millisecond redundancies, and protect sensitive data.

AGV & AMH

Auto Material Handling systems will play an increasingly large part in increasing productivity in both manufacturing facilities and warehousing.

They will enable the removal of unproductive processes from facilities, not only making them more efficient but increasing the visibility of outputs.

Wireless AP and Smart switches provide the perfect spine for AMH systems. With the ability to manage multiple protocols, easily integrate with an existing SCADA system, fast rebooting for maximum availability, and with low power consumption.

Project support

Our Industry specialists are here to support through design and product selection for your network topology. We can help you find the right products to save you time, money and ensure the success of your project. Register your project with the Industrial IT team.